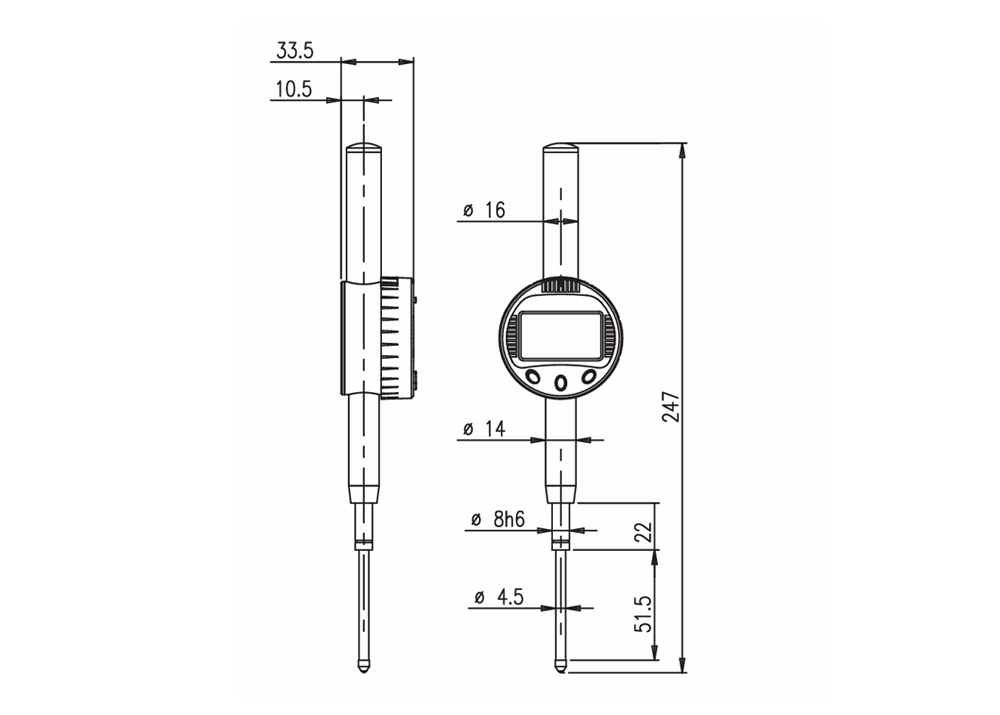

Cyfrowy czujnik zegarowy 0-50,8 mm z wyświetlaczem LCD do metrologii i inspekcji

-

Podkreślić

Wskaźnik cyfrowego wybierania kontroli

,0-50

,8 mm cyfrowy wskaźnik wybierania

-

GwarancjaRok

-

TypWskaźnik cyfrowy

-

PomiarMetryka/cal

-

Zakres0-50,8 mm/0-2 "

-

Rezolucja0,001 mm/0,00005 "

-

Z powrotemPłaski tył i tył z uchwytem

-

Max Siła pomiarowa1,6 n

-

CzapkaStała i ruchoma czapka

-

PakietPudełko ABS

-

Miejsce pochodzeniaShaanxi, Chiny

-

Nazwa handlowaKM

-

OrzecznictwoISO DIN GB RoHS

-

Numer modeluKM-232H-50.8

-

Szczegóły pakowaniaPudełko ABS 30*21*12 cm/kawałek 0,78 kg/kawałek

-

Czas dostawyW ciągu 15 dni

-

Zasady płatnościT/T, L/C, D/P, D/A, Western Union, PayPal, Moneygram

-

Możliwość Supply50000 miejsc/miesiąc

Cyfrowy czujnik zegarowy 0-50,8 mm z wyświetlaczem LCD do metrologii i inspekcji

Wskaźnik cyfrowy stosowany głównie do sprawdzania zmienności tolerancji podczas procesu kontroli części obrobionej, pomiaru odchylenia

w warunkach laboratoryjnych, a także w wielu innych sytuacjach, w których małe pomiary muszą być zarejestrowane lub wskazane.

Elektroniczny cyfrowy wskaźnik tarczy ma duży wyświetlacz LCD, który może szybko i precyzyjnie zmierzyć wymiary obiektów i możemy łatwo

uzyskać wyniki pomiarów poprzez po prostu obejrzenie liczb na wyświetlaczu, bez konieczności wykonywania skomplikowanych obliczeń lub konwersji.

To jeden ekonomiczny cyfrowy wskaźnik tarczy o konkurencyjnej cenie, funkcje z funkcjami konwersji metrycznej / cali, przechowywania danych i pozycjonowania absolutnego,

co czyni go idealnym do wykonywania zadań wymagających wysokiej dokładności.

- Duży wyświetlacz LCD dla łatwej lektury.

- Możliwość konwersji metrycznej na cal.

- Tryby pomiaru bezwzględne/rozszerzone.

- Funkcja włączenia/wyłączenia.

- Możliwość zerowego ustawienia.

- Sterownik pojemnościowy.

- Aerometalowa konstrukcja nadwozia.

- Funkcja wyjścia danych.

- Zawiera zabezpieczającą obudowę.

| Rozkaz nr. | Zakres | Rozstrzygnięcie | Dokładność |

|---|---|---|---|

| KM-232H-12.7 | 0-12,7 mm/0-0,5" | 00,001 mm/0,00005" | ± 0,004 mm |

| KM-232H-25.4 | 0-25,4 mm/0-1′′ | 00,001 mm/0,00005" | ± 0,005 mm |

| KM-232H-30 | 0-30mm/0-1.2′′ | 00,001 mm/0,00005" | ± 0,005 mm |

| KM-232H-50.8 | 0-50,8 mm/0-2" | 00,001 mm/0,00005" | ± 0,006 mm |

- Należy utrzymywać twarz wskaźnika w czystości i zapobiegać wnikaniu płynu.

- Unikaj wstrząsów, uderzeń lub upadków, aby zapobiec uszkodzeniu wyglądu i precyzji.

- Nie stosować w bezpośrednim świetle słonecznym ani przechowywać w ekstremalnych temperaturach.

- Nigdy nie podłącz żadnej części wskaźnika do źródeł napięcia.

- Nie usuwać pokrywy końcowej bez użycia interfejsu wyjściowego; unikać kontaktu metalu z końcem wyjściowym.

- Wyjąć baterię, gdy nie jest ona używana przez dłuższy czas.